Our Services

Our specialization is De-erection and re-erection of major WTG parts incl. Nacelle, Gearbox, Generator, Rotor and Single blade with a Crane-less lifting Technique without any crane support. Development is going on for higher MW Wind Turbines.

A GLANCE ON OUR SERVICES

- Wind Resource Assessment

- Micrositing

- Gear Box service division

- Project development

- Nacelle & Rotor Assembly & Erection

- Tower Assembly & Erection

- WTG Installation & Commissioning

- Turnkey projects incl Cranes, &Transportation

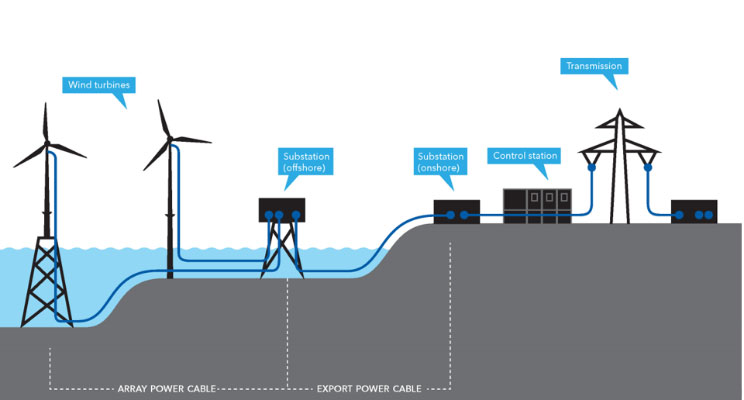

- Operation & Maintenance of WTGs & substation

- Dismantling/Decommissioning of wind farms

- Assisting Purchase & Sales of Old

Turbines & Reconditioning of such WTGs

- SCADA support for Operational assistance

- Special work related to Turbine failures

- Installing and Servicing Wind turbines

Operation & Maintanence

– More than 100 MW Turbines under our O&M

– Almost all Indian Wind Turbines models are in our O&M portfolio

– We employ close to 100 technicians for O&M & Winch work.

– Dedicated on-site team for 24 x 7 to attend the Turbine immediately.

– We offer Simple , Semi & Comprehensive O&M as per customers’ choice.

– We offer Maintenance of Wind Turbine Generators, Substation, High Tension Lines and Assembling.

– SCADA support for operation of wind turbine and maintenance.

– We maintain sufficient spare parts to minimize Turbine down time.

– We continuously work towards technology & process upgradation to improve the operational efficiency at minimal cost.

Training & Development

NWPPL is always believe in effectiveness of Training in improving the Efficiency in Work & Safety practices

NWPPL employees are provided with all trainings listed below

- Induction Program

- 5 S Training for basic shop floor discipline

- On the Job Training

- Special skills that are required.

- Use of PPEs

- Fire fighting

- Work at Height

- Basic Life support & First Aid

- Mock Drill

- Rescue Training

- Electrical safety

Operational Excellence & Leadership

NWPPL is always able to achieve the Excellence in Operation with its Motto of

– Quality approach in every activity

– Continual improvement in process

– Continuous stride in Technology to improve operational efficiency.

– Ensure Safety in every activity

– Dedication & Commitment